Soap making machine 2000kg per hour laundry soap production

line from Chinese soap machinery production factory

Ⅰ.Brief Instruction:

This soap line is used to produce laundry soap with fatty acid content from 50% to 80%. Material is soap noodle. Capacity is 2000-2500 kg/hr.

The dimension and pattern of the soap can be made by customer’s requirements.

It is an advanced model of soap making machine with sigma mixer and two sets of oil sealed three roller mill. So the end soap quality would be super high.

Contact parts of machine are made of stainless steel 304.

Ⅱ.Production Condition:

1.Materials: soap noodle, pigment, fragrance, etc.

2.Workshop: above 180 m², L: 30 m, W: 6 m, H: 4 m, including operating space, excluding packing machine.

3.Power: 200 KW, 380 V, 50 HZ.

4.Staff: 5~8 persons.

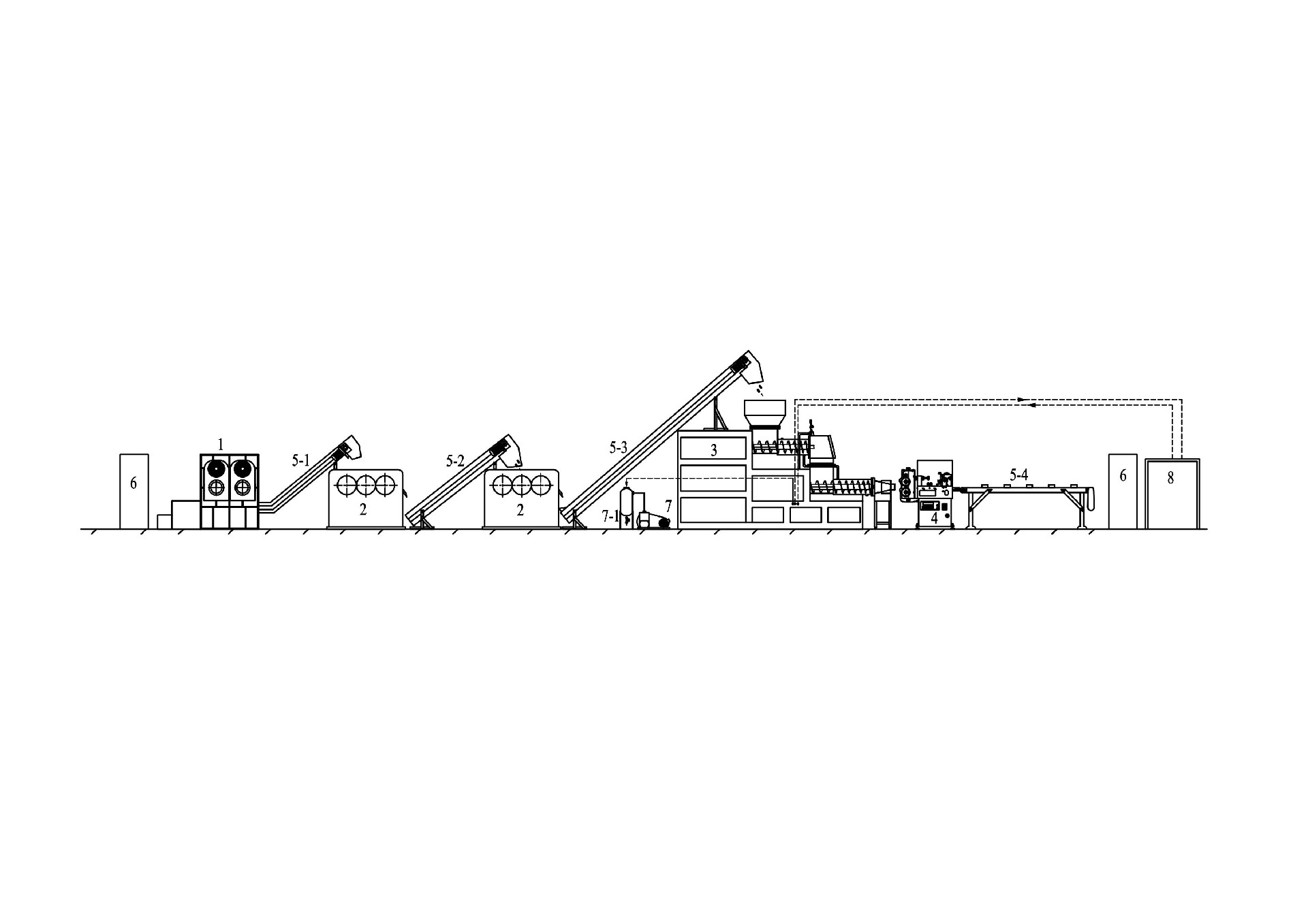

Ⅲ.Flow Chart:

Ⅳ.Production Process:

Mix Materials →Grind & Refine →Extrude Soap Bar →Cut and Stamp Soaps

from laundry soap noodle end into laundry soap

Our Product Advantages

Our Company&Services

Jinan Zhonghui Machinery Manufacture Co.,Ltd is founded in the year of 2009. We are a professional factory

focus on the design, manufacture and technical service of soap,glycerin and fatty acid equipment.

Our company has passed the ISO9001 Quality System Certification. We can provide turn-key

project,including the technique design,machine fabrication,workshop layout,machine

installation&commissioning,staff training,etc.

Our products has been exported to more than 62 countries and regions all over the world.

---services

Our chief engineer has worked in this soap industry for over 20-30 years. We not only know how to make machines, but also know how to operate them. We provide comprehensive technical assistance to our customers and ensure that each customer, whether new or experienced, can well build and operate their own soap factory. We will ensure that every customer receives a high profit from our machines. We help you find the most suitable and competitive soap product line for your target market. We help you draw drawings of the workshop building and equipment layout. We provide you with high-quality and stable performance soap machines, spare parts, and accessories as a turnkey project. We send engineers to your location for machine installation, staff training, etc. We provide consistent technical support during the whole life span of our machine.

<< Previous

Next page >>