For the soap production, normally it has two steps, first step is to use all kinds of vegetable oil & animal fats and caustic soda (NaOH)as material to produce the semi product soap noodles and the second process is to use thus soap noodles as material to produce out end bar soaps.

In these two production lines, we have our own unique design and patented technology, especially the production line starting from oil saponification. Using vacuum drying and continuous molding processes, we can produce various specifications of semi-finished soap noodle and soap products with a fatty acid content of 45% to 80%.

Basic production process:

Oil melting & mixing (based on formula requirements)→ Saponification (no waste-water discharge)→Vacuum drying &Pelletizing (produce out soap noodles)→ Soap finishing line (produce out end bar soaps)

for Soap Noodle Production Line:

This is a line specially designed for the customer's that planned to sell the semi product soap noodles directly to the market. The basic process includes oil de-coloring & refining, oil saponifying, vacuum drying and pelletizing to produce out the soap noodles. End soap noodle could be different quality grade with fatty acid content range 50%~80%. And the soap noodle would have even size and smooth appearance, which ensures its high competitive ability in the market.

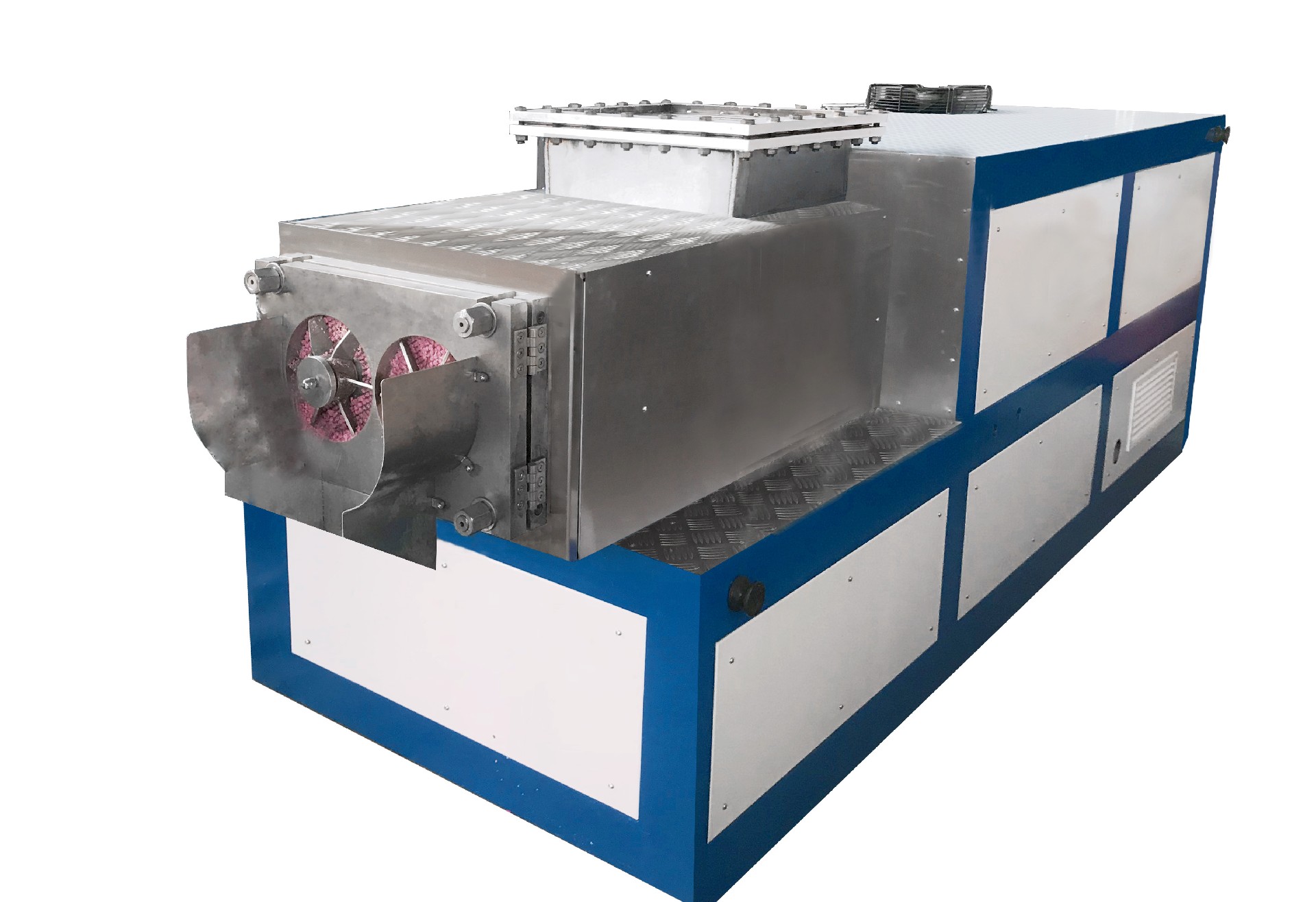

Raw Material Maker Stainless Steel 304 2000kg per hour Double Screw Soap Pelletizers Refiner for soap noodle making

When it is mounted under the vacuum spray chamber,it will be act as a soap pelletizer,when it is used in a soap finishing line,it will act as soap refiner.

Working Principles:

Designed to refine and press the soap flakes from vacuum dryer, increase the density and transparency of soap, and then knife equipped at the pelletizing mouth would cut soap flakes into soap noodles.

Its working principle is to use the transmission of the spiral blade to make the soap flakes fully contact and squeeze inside the cylinder wall. The rotating screw blade, its own weight and the friction between the shell make the soap flakes moving forward and transporting to the muzzle, then soap flakes are cut into granules by the orifice scraper on the nose to become soap noodles (semi-finished products).

Technical Parameters:

| Product name | pelletizer/granulator/soap noodle making machine |

| Model | XT-2000 |

| Material | parts that touch with soap material all made of stainless steel 304 |

| Capacity | 2000~2500kg/h |

| Power | 18.5kw |

| Screw diameter | 230mm*2 |

| Screw type | double screw |

Characteristics:

1.The structure is welded strong and neat;

2.The extruding cylinder made from thick wall cold drawn seamless tube, together with the thickened screw, ensures to create high enough pressure and

produce high quality soap noodles,and the circulating water cooling of the spiral blades ensure the high quality requirements for soap nuggets;

3.Siemens Beide Brand frequency conversion motor and Guomao Brand horizontal hard tooth reducer are adopted, ensure the machine to have stable performance, high efficiency, automatic lubrication and low noise;

4.It adopts transmission deceleration and separation, convenient maintenance and long service life.

Our Company&Services

Jinan Zhonghui Machinery Manufacture Co.,Ltd is founded in the year of 2009. We are a professional factory focus on the design, manufacture and technical service of soap,glycerin and fatty acid equipment.

Our company has passed the ISO9001 Quality System Certification. We have finished the registration of “ZHONGHUI” brand as our trademark;

We have got several patents for our soap machine design and fabrication function;We can provide turn-key project,including the technique design,machine fabrication,workshop layout,machine installation&commissioning,staff training,etc.

Our products has been exported to more than 62 countries and regions all over the world.

---SERVICES

Our chief engineer has been working in this soap industry for nearly 30 years. We not only know how to make machines, but also know how to operate them. We provide comprehensive technical assistance to our customers and ensure that each customer, whether new or experienced, can well build and operate their own soap factory. We will ensure that every customer receives a high profit from our machines.

--We help you find the most suitable and competitive soap product line for your target market;

--We help you draw drawings of the workshop building and equipment layout;

--We provide you with high-quality and stable performance soap machines, spare parts, and accessories as a turn-key project;

--We send engineers to your location for machine installation, staff training;

--We provide consistent technical support during the whole life span of our machine.

<< Previous

Next page >>