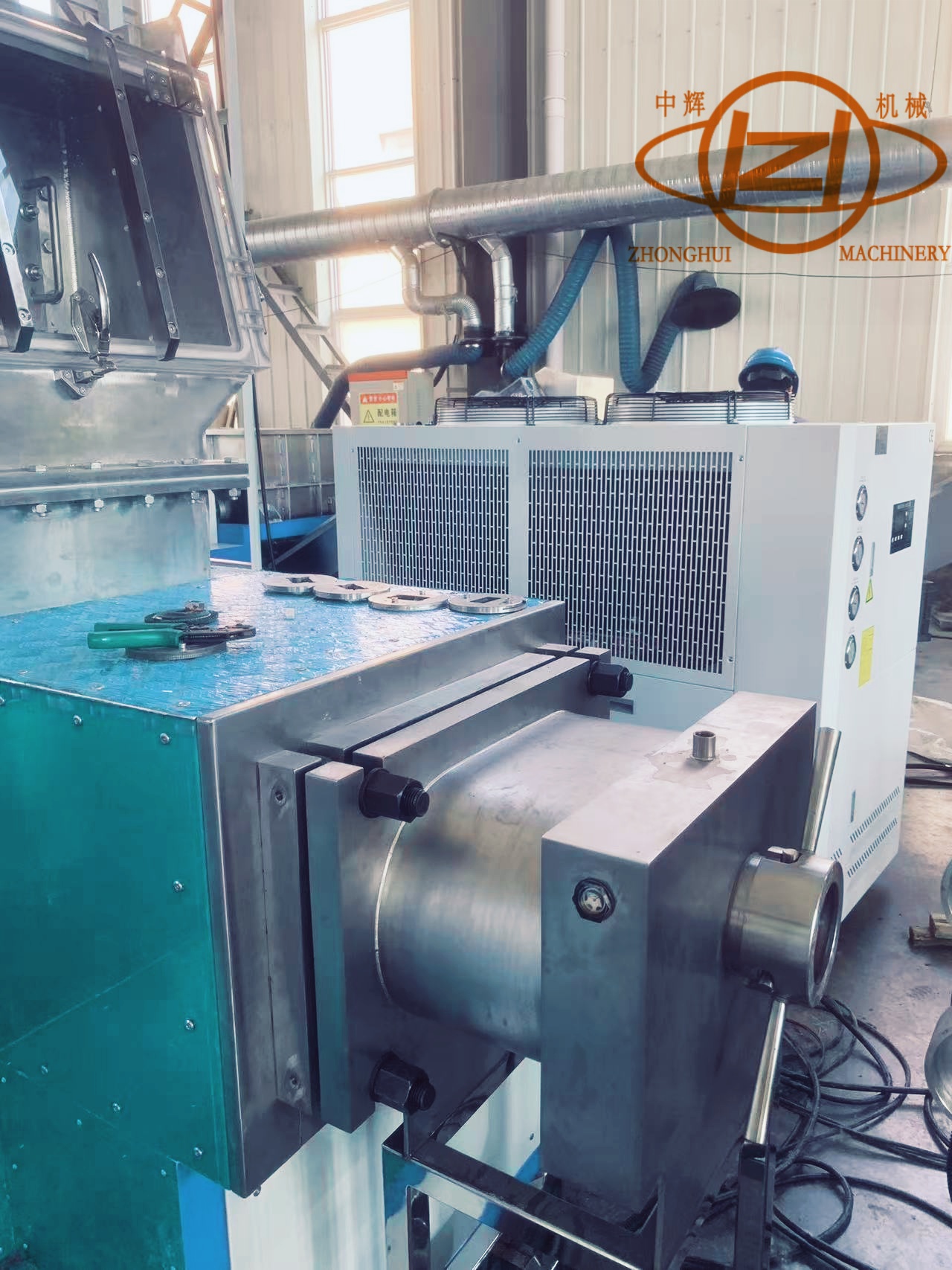

Control the temperature of the soap:When the soap strips are extruded by the machine, due to mechanical compression and friction, the temperature of the soap strips will rise. If the temperature is too high, the components in the soap may change, affecting the quality and performance of the soap. For example, certain fragrances or additives may volatilize or deteriorate due to high temperature, resulting in changes in the fragrance and efficacy of the soap. The cooling machine cools the extruder, which can effectively control the temperature of the soap strips and keep them within an appropriate range, ensuring the stability of the soap quality.

Improve the appearance of the soap bars:If the soap strips are too hot, they may have problems such as uneven surfaces and deformation after extrusion, which will affect the appearance quality of the soap. The cooling machine lowers the temperature of the extrusion machine, which helps the soap strips to be quickly shaped, making the surface of the soap strips smoother and more flat, and the shape more regular. This improves the appearance quality of the soap and makes it more competitive in the market.

Improve production efficiency:When the temperature of the strip production machine is too high, the operating speed of the equipment may be restricted. Otherwise, it is prone to malfunction or affect the quality of the soap strips. The cooling machine cools the strip production machine, allowing the equipment to operate at a more suitable temperature, enabling an increase in the strip production speed and thereby improving production efficiency. At the same time, the hardness of the soap strips after cooling increases, making subsequent processing steps such as cutting and printing easier to operate, reducing processing difficulties and defective rates caused by overly soft soap strips.

Protective equipment:Operating for a long time in a high-temperature environment will accelerate the wear and aging of the strapping machine equipment, reducing its service life. The cooling machine can lower the working temperature of the strapping machine, reduce the impact of thermal stress and thermal deformation on the equipment, extend the maintenance cycle and service life of the equipment, and lower the equipment renewal and maintenance costs of the enterprise.

<< Previous

Next page >>